What is the study about?

The study compares the environmental impact and life cycle costs of various low-noise road surfaces (LAB) with those of a conventional road surface. The study not only looked at the construction, maintenance and demolition of the road, as has usually been the case in the past, but also at the use phase, i.e. the use by cars and trucks and the associated environmental and cost consequences. This meant that differences in road noise emissions, tire wear and energy consumption depending on the road surface could also be included in the study.

What methodology did we use?

In our life cycle assessment in accordance with ISO 14040 and the life cycle cost analysis, we compared four scenarios with each other and examined five further sensitivity analyses for future development and optimization. We examined four different road surfaces for a typical main road in an urban area (average population density, speed 50 km/h, 8000 vehicles per day) - these differ primarily in terms of their service life and the noise reduction achieved:

- Reference: a conventional road surface with a service life of 20 years (ACMR 8)

- LAB 1: a semi-dense, very low-noise road surface with a service life of 10 years (SDA 4)

- LAB 2: a semi-dense, low-noise road surface with a service life of 15 years (SDA 8)

- LAB 3: an acoustically optimized asphalt concrete with a service life of 20 years (AC 8 H LA)

We modeled the construction and maintenance processes based on the LCA database of the Federal Office for the Environment (UVEK:2023) and expert knowledge from interviews. We were able to model the usage processes thanks to our databases on noise reduction and rolling resistance. To ensure that the results are comparable regardless of the service life of the pavements, we calculated the analyses "per km of road and year".

We calculated the results in the impact categories of environmental impact points (EP), greenhouse gas emissions (CO2 equivalents), non-renewable primary energy demand (MJ) and costs in Swiss francs. In addition to direct costs, e.g. construction costs or fuel costs, external costs were also taken into account. External costs are not borne by the polluter, but indirectly, e.g. by residents, homeowners or society in the form of health costs, loss of rent or climate damage. The effects of road noise emissions could thus be reflected and taken into account both in the costs and in the environmental impact points.

What are the most important findings?

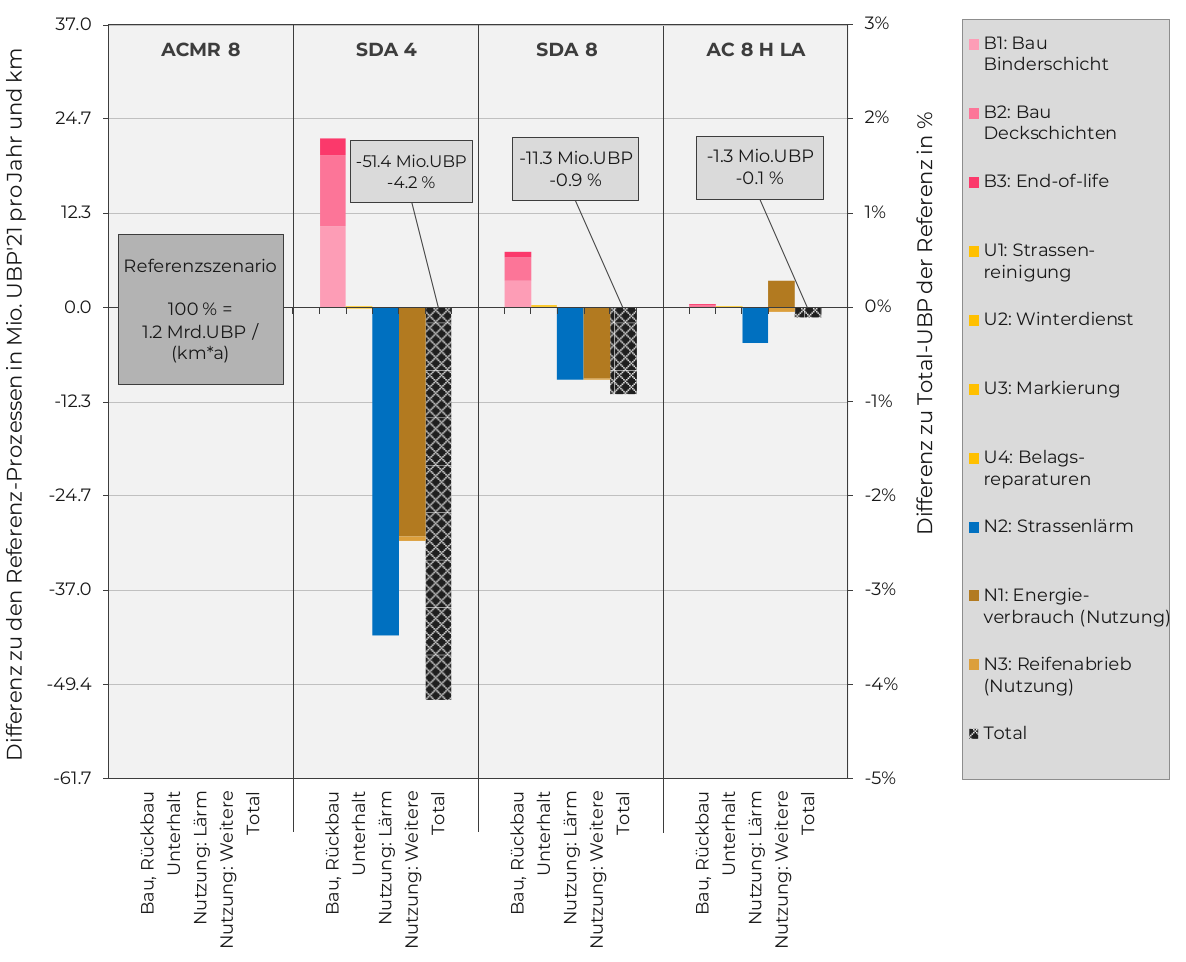

- From an overall ecological point of view, the advantages of low-noise road surfaces from the use phase outweigh the disadvantages due to their shorter service life. This means that the total environmental impact is reduced by approx. 4 % when using SDA 4 compared to the ACMR 8 reference surface. This is over 50 million UBP per kilometer and year, which corresponds to approx. 135,000 passenger car kilometers saved.

- The LAB also proved to be advantageous in terms of life cycle costs compared to the conventional ACMR 8 reference surface: if both direct and external costs over the entire life cycle are taken into account, the use of an SDA 4 surface can save over 6% of the costs, which corresponds to around CHF 66,000 per year and kilometer. There is a cost shift here: LABs cause higher costs for developers, but reduce costs and follow-up costs for users and residents, or society as a whole.

- The SDA surfaces are not only advantageous thanks to the reduced road noise emissions, but they also reduce the fuel and energy consumption of road users: the rolling resistance of SDA 4 surfaces is over 10 % lower than that of ACMR 8 surfaces. This means that 3% less energy is consumed over the entire use of the road, with corresponding positive consequences in all four impact categories.

- In the impact categories of greenhouse gas emissions and non-renewable primary energy demand, the benefit of noise reduction from LABs cannot be taken into account; here the differences between the scenarios are smaller, but for the most part point in the same direction, which is advantageous for SDA surfaces. In general, the "LAB 2" scenario (SDA 8) has comparable results to SDA 4. However, these are much less pronounced. "LAB 3" (AC 8 H LA) mostly shows results comparable to the reference scenario.

- The five sensitivity analyses confirm the robust validity and directional reliability of the results. Of particular interest is the potential for optimizing road surfaces with regard to reduced rolling resistance. Costs and environmental impact points can even be reduced by a total of 8% and 6% respectively with the best road surfaces already in use today. In addition, a future scenario with a high proportion of eclectically operated cars shows that the results will continue to be valid in the future and that noise protection with LAB will remain sensible, useful and sustainable.

The benefit of this study?

The results of this study are of direct relevance to noise abatement authorities, road planners and acousticians as they provide a holistic assessment of the environmental and financial impacts. These findings provide a solid basis for the evaluation of road construction projects and noise protection strategies. This study thus makes an important contribution to the promotion of an environmentally friendly and cost-optimized road infrastructure in Switzerland and also offers valuable insights for other countries wishing to use low-noise road surfaces in urban areas.

What further action is required?

In view of the recent adoption of the revised CO2 Act by the Swiss parliament for the years 2025 to 2030, which aims to halve CO2 emissions by 2030 compared to 1990, it is time to quickly start implementing projects to reduce CO2 emissions.

Our study clearly shows that civil engineering can and must make a significant contribution to these goals. There is a strategic need for action to evaluate road infrastructure projects as holistically as possible in order to improve their sustainability. In addition to the net benefit of noise abatement with LAB shown here, the great, as yet barely exploited potential of road surfaces with improved rolling resistance properties is particularly evident.

Acknowledgments

The study was carried out together with our partners from ArGe LCA-Strasse:

- E2 – Sustainability in Business: Arthur Braunschweig

- HK Partners – Global Sustainability Expertise: Rolf Huwyler

We would like to thank our client, the Federal Office for the Environment FOEN, as well as the additional funding partners Canton Aargau, Canton Zurich and Canton St. Gallen.

We would also like to thank all the experts who shared their valuable knowledge for this study through their work on the monitoring committee and as interview partners.

/www.gundp.ch/file/2379/Slider_LAB_LCA_v2.png)

/www.gundp.ch/file/2378/Slider_LAB_LCA_Waage.png)

/www.gundp.ch/file/1453/Internoise2018_ChicagoSkyline_cmprsd.png)

/www.gundp.ch/file/1712/Webinar_SonRoad18_Quadratisch.jpg)

/www.gundp.ch/file/1810/Quadratische_Internoise2022.jpg)